GENDER POLITICS IN CLOTHING TECHNOLOGY

The Social Shaping of a Female Workforce

Juliet Seger

2020

This essay was first submitted within the course Understanding Technology (2019/2020)

at the School of Social and Political science at The University of Edinburgh.

Introduction

Science and Technology Studies (STS) assign increasing importance to gender-politics. The canon usually refers to a structural exclusion of females within the fields of engineering, science and technology (Wajcman, 1991: Grint & Gill, 1995; Faulkner, 2000). However, there seems to be a unicorn in the world of engineering: The discipline of Clothing Technology shows a strong female presence.

The aim of this essay is to draw attention to this dynamic that is unprecedented in other fields of technology. I will highlight that Clothing Technology is not in itself female (technological determinist view) but that this character trade is shaped by society. As a tailor and clothing engineer I feel competent to complement secondary literature with personal observations. The starting point will be an outline of the appropriateness of gender studies in STS. I will sketch the concept of Social Construction of Technology and the content of the discipline of Clothing Technology. The two topics will be linked in observations of female majority in the industry. The role of women in garment manufacturing is seen as of great importance and is thus attended to in a separate section. This beats the bow to digitalism in the industry’s future, incorporated in the world of ‘Fashion Tech’. I finally address arguments of technological determinism towards gender in sewing technology before concluding with a nod towards the potential of transforming historically inegalitarian constructivism into future female empowerment and gender-equality.

Relevance of gender studies in STS

“[The] technology industry (…) has a woman problem. It is so overwhelmingly male as to suggest widespread institutional misogyny, if not gynophobia (Schroeder, 2016:755).”

“Machinery is designed by men with men in mind; industrial technology reflects male power (…) (Wajcman, 1991:49).”

“The cultural association between masculinity and technology in Western societies is hard to exaggerate (Grint & Jill, 1995:3).”

Data on gender quotas of related industries show that the notion of ‘male’ technology is not an urban legend, not a relic from pre-developed times stuck in society’s memory or an argument used to evoke yet another quarrel around male supremacy. Along various levels and branches of science and technology – students, graduates, work force, management, research – we witness a growing, but still low percentage of participants who identify as female (Destatis, 2019:94; The Women’s Engineering Society, 2018). As technology is increasingly relevant in everyday life, people are less often agents of their own choice, but are object to electronic processing and evaluation of information. Technological systems and algorithms are introduced into governmental and administrative procedures, recruiting, banking, shopping and a never-ending list of digital services. In light of the rapid digital evolution it is not surprising but important to note a wide-spread illiteracy on how these technologies work and how they work on us – inevitably drawing the link to who works them? Understanding these operations needs analysis of how pre-valent and niche concepts of gender, class and ethnicity shape technology and vice versa are shaped by it. Useful thoughts and tools for this endeavour can be found in Science and Technology Studies. A strength of this field of academia can be applied to Clothing Technology: in referencing ethnographic studies, its concepts are often aimed at being useful for the most excluded or marginalised entity and thus highlights moral debates (Williams, 2019).

Social Construction of Technology

A constructivist perspective on the world leads to the concept of Social

Construction of Technology. Pinch and Bijker (1984) point out that technological artefacts are dependent on the meaning given to them by relevant social groups and structures. The motivations

behind constructing a technological system define whether it is understood as working well and as ‘the best’ system. This ‘interpretative flexibility’ will be followed by the

‘stabilization’ (that is acceptance) of the artefact and its properties within society. The omnipresence of female stakeholders in Clothing Engineering and the surrounding dynamics hint

towards the social shaping of the industry’s gender politics.

Gender in Clothing Technology

The following will give a quick overview of the content of the discipline and provide insight into the gender-ratio across a diverse range of institutions and processes.

Tertiary education in Clothing Technology concludes with a diploma in engineering. The discipline looks at every stage of a textile product’s life, ranging from fibre polymer production to post-consumer recycling. It draws heavily on natural sciences, integrating foundations of mathematics, physics, chemistry and biology into research and product development. Exemplified along university course modules Clothing Technology includes but is not limited to: textile chemistry, textile finishing, manufacturing engineering around pattern cutting (manually and through CAD), sewing technology and automation. In its application it is inevitably linked to supply chain management, work studies, business and marketing. In short: while working closely with design, Clothing Technology covers all technical processes necessary to create a textile product or system. The product development in particular is closely linked to vocational training programmes such as tailoring.

Quantitive data on the structure of the fashion and textile workforce is difficult to obtain. Recollections from experience along my career in Clothing Technology however illustrate a strong female presence in this field of engineering: Throughout three years of tailoring training with a European fashion brand, a hundred percent of apprenticeship colleagues were female. The prototype manufacturing division comprised of three men and fifteen women. The pattern cutting division held an entirely female workforce. In total, the local headquarter comprised of an estimated eighty percent women. The quota at the accompanying vocational college course was twenty-two women and two men. There are currently 272 women and 25 men enrolled across undergraduate and postgraduate level of Clothing Technology at Hamburg University for Applied Sciences (Schempp, 2019). International comparison signals similar structures: Graduates of The Fashion Institute of Technology in New York comprise of 86 percent women (Friedman, 2018). Necessarily the trend reaches outside of universities. My internships in tailoring and fashion in Germany (2009 and 2012) were situated in all-female studios. Another work placement in the U.S. was headed by male CEOs and CFO while the roughly hundred employees consisted of an estimated ninety percent women.

The garment industry – as per usual – contains a mid-career wall, shifting the gender-balance in higher positions despite a high quota of women at entry level and in positions of specialised skills. “(…) [A Business of Fashion (BoF)] survey of 50 major fashion brands revealed that just 14 percent were run by a woman (Pike, 2016).” Such gender-hierarchy plays a role in terminology related to the industry. German language traditionally entails bending job titles according to gender, with the male version being frequented as ‘gender-neutral’, a practice often criticised. In this, the German clothing industry should be awarded head-of-the-game in their practice of always referring to a sewing machine operator as ‘Näherin’ (female), never to ‘Näher’ (male). Equivalent, the English male version of ‘seamstress’ is hardly in use (‘seamster’? ‘closer’?; see figure 1). Stepping up one level of qualification, English language refers to the male connotated title of ‘tailor’ (see figure 2).

Figure 1: Results for Google images search for 'seamstress'; Edinburgh, 25/11/2019.

Figure 2: Results for Google image search for 'tailor'; Edinburgh, 25/11/2019.

Women in Garment Production Technology

A high variety of machines, tools, systems, actors and institutions engage in garment production. Especially along the manufacturing steps of cutting, sewing and trimming we find a fundamental characteristic of this industry: the dependency on human labour. This is due to (1) economic, organisational structures as well as to (2) unique properties of textiles. The former (1) expresses itself as dependency on low-wage labour without which the supply and resulting demand of products in consumer markets could not be satisfied. As sewing is not dependent of geographic location, communities with poor wage standards are interchangeable and promise further resilience of the system. Managerial and production processes are not only separated by class, but also across national boundaries (Mills, 1999:9). Ninety percent of clothes consumed in Germany are imported from developing countries (BMZ, 2018). As the fast fashion industry has marked its dominance, e.g. making H&M and Zara industry leaders (Degenhardt, 2019:30), companies offer a constant change of products. The variation of styles, fabrics and finishing lowers the produced units and requested lead times for each piece, limiting standardization of processes while demanding heightened flexibility in manufacturing. Catering to these needs efficiently requires human labour and limits the use of automation. (2) The properties of fabrics, especially the floppiness and variety of surfaces, makes digital processing difficult. Where automation is in use, foremost in standardised menswear, only components of the product are processed, such as sewing together two layers of a shirt collar, leaving it to humans to invert, press and attach it to the bodice. Finally, fast fashion garment production involves a high division of labour and low quality. Tasks of high repetition and low complexity require little previous qualification and thus can be executed by many. The link of human labour to the textile industry concludes with the fact that one third of workers worldwide are connected to it, herein exceeding the automotive industry (Von Wedel-Parlow, 2015:67).

A striking amount of eighty-five percent of garment workers are female (Von Wedel-Parlow, 2015:67). It is important to recognise this omnipresence of women not as a plain characteristic of this world of labour but also see its social implications. The anthropologist Mary-Beth Mills explores the social dynamics around a female workforce in her book ‘Thai Women in the Global Labor Force’ (1999). Her focus lies on individual motivations, kinship ties and pressures as well as economic dependencies around rural-urban migration of young women who catalysed Thailand’s economic boom in the 1980s. She brings to attention that each clothing product consumed in industrial countries was most likely manufactured by an underpaid woman. In the context of rural-urban migration, employers identify young women as only temporarily engaging in work, prior to marriage, thus creating a high turn-over in employees. “Consequently, women workers are more likely to put up with low pay, limited benefits, and long-term job insecurity. Their youth and gender also suggest a work force already schooled in obedience to (parental) authority, hard work, and the patience and dexterity required for many domestic chores (such as weaving and sewing). As a result, women’s character and skills are often seen to be particularly well-suited for the fine detail and endless repetition of textile and electronics assembly work (Mills, 1999:7).” Mills makes an important observation for the implications of gender on technological development: While historically female workers have often functioned as catalyst for the industrial revolution (cotton and silk thread mills in Japan in the late nineteenth century; Yankee women in the first cotton mills in the United States in the early 1800s), the modern world has rapidly introduced technological labour into communities that “a generation ago (…) [limited their female workers to agriculture], small-scale vending, domestic service or prostitution” (Mills, 1999:8). The repetition of this pattern in the most diverse areas of the world is claimed to be striking.

Bangladesh follows dynamics of Thailand and is an excellent example for economic development built on a predominantly female work force. The garment industry contributes eighty percent of the country’s exports (Brühl, 2013) and is understood to be the driver of Bangladesh’s rapid GDP growth of 7.87% (BMZ, n.d.). Attention: Eighty-five percent of the 4.5 Million Bangladeshi garment workers are female, the working conditions poor (Schultze, 2014; Weber-Steinhaus, 2019).

In her book “Feminism Confronts Technology” (1991), Judy Wajcman delves into a broad spectrum of discussions around male supremacy in technology. She assigns production technology and paid work the strongest conjuncture of technology and the social as livelihoods depend on it and people spend most of their time at it (Wajcman, 1991:27). She identifies that “female labour is usually accompanied by a down-grading of the skill content of the work and a consequent fall in pay for the job (Wajcman, 1991:37)”. The decrease in this is not a decrease of actual capability to fulfil a task, but rather a shift of what is considered skilled work and what is not. Exemplified in the traditionally female sphere of nursing, which requires technical knowledge, but is not considered a skill it becomes comprehensible: “Definitions of skill can have more to do with ideological and social constructions than with technical competencies (…) (Wajcman, 1991:37).” Further, women’s wages are generally lower than men’s. Technological innovation, such as automation, will only be sought for if the return on invest exceeds the labour costs. Wajcman makes the following link: Historically, women are accredited a natural aptitude for sewing. In male technological supremacy this is not defined as skill and is therefore undervalued and underpaid. In consequence the male-headed, capitalist garment industry has had access to cheap labour power and less incentive for modernisation (Wajcman, 1991:49). In perspective of the low numbers of men in the garment industry’s technical training versus the male dominance in managerial positions, Wajcman’s argument seems to have found evidence: If stakeholders with experience in sewing technology are not included in higher positions, how can the true value of sewing skills be incorporated in decision-making?

Women in Fashion Tech

In light of digitalisation the realm of fashion and functional textiles has opened up to innovations around smart textiles (e.g. with heat sensory and regulative properties), wearables (e.g. attached communication devices) and digital manufacturing (Butkovic, 2019). Enhanced functionality of smart textiles and wearables require adaption in the process of production. Digital manufacturing however has potential to fundamentally transform this field. It is an “(..) integrated approach to manufacturing that is centered around a computational system using tools such as 3D technologies, robotics, AI and AR and the integration between digital technologies for manufacturing processes and embedded digital technologies in products-services to enable open and distributed manufacturing that can reshaped design, production, distribution and retail processes (Butkovic, 2019).” Current leaders in research around these technologies are the sportswear brands Nike and Adidas. Their products are characterised by a low variation in shape and a focus on knitted textiles produced in high quantities. Innovation includes ideas of the ‘speed factory’ (Adidas), the implementation of ‘sewbots’ (Adidas; Innovation in Textiles, 2017) or 3D printed components of running shoes (Adidas, 2019; Nike, 2019). As a discussion on the future of digitalisation within the textile supply chain could saturate an essay of its own – When, if, for which products will this be used? Will it benefit or harm garment labour? – it is here important to acknowledge its potential impact on future consumption, labour of production and the above-mentioned female workforce. As in other industries, fashion will further be influenced by incorporation of data analytics, artificial intelligence, social media and related algorithms to guide business decisions (Butkovic, 2019; see also Degenhardt, 2019:19).

Contrasting the number of female stakeholders in the field of Clothing Technology with the male dominance of the business sector, draws light to an interesting dynamic. The majority of investors and venture capital firms consist of male partners. “And since men network with other men within their network, they also invest more in male-led startups and businesses. Venture firms with women investment partners are 3 times more likely to invest in companies with female CEOs (Butkovic, 2019).” In 2018, only seventeen percent of venture capital deals in the UK went towards enterprises with women on their founding teams (British Business Bank, 2019a) and merely one percent of venture capital investment is distributed to all-female led teams (British Business Bank, 2019b). This questions the future of gender-diversity in ‘Fashion Tech’, holding the potential of repeating historic shortcoming of technological developments in regard to reinforcing structures of gender inequality but also missing out on a gendered lens towards the desires of female consumers. On this Burak Cakmak, dean of the fashion department at Parsons New School of Design New York: “[Innovation] (…) necessitates a more collective approach, which should by definition be more inclusive (Friedman, 2018).”

A technological deterministic approach: “Sewing is for girls”

Though I have already given away a subjective tendency towards the opposite, it is necessary to address potential arguments in favour of technological determinism in the gender-politics of Clothing Technology.

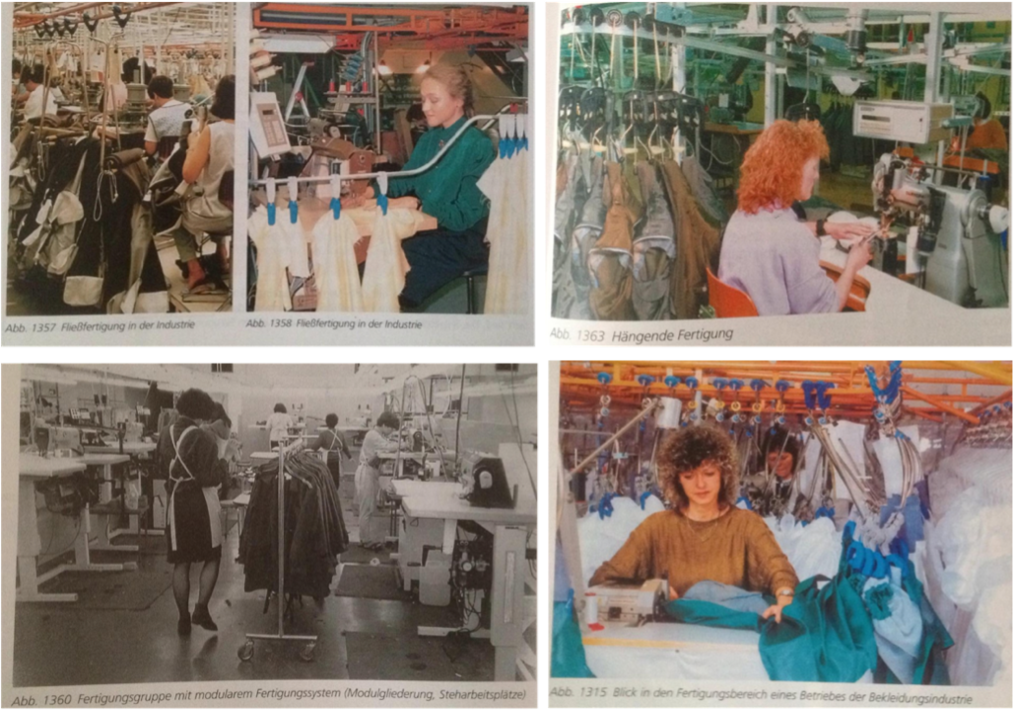

MacKenzie and Wajcman (1999) label Technological Determinism as “a very common way of thinking (MacKenzie & Wajcman, 1999:5)”. It entails that “the intrinsically best technology will ultimately triumph (ibid.).” If ‘the best’ is interpreted as the most economically efficient, then yes, one could argue that contemporary Clothing Technology has manoeuvred itself into incorporating the cheapest component into its system (women). Technological determinism sees technology as independent force that develops in an inevitable manner, impacting the surrounding society to adapt towards it. In context of the lack of gender-balance in Clothing Technology this would assume that its technology is just plainly more suitable for female actors. Some aspects of garment manufacturing may imply that a women’s physique could be more fit to execute certain tasks. One example would be traditional spinning processes that were predominantly executed by females. Their slender fingers are said to have been more capable of tying up loose and broken ends of wool or cotton strands (New Lanark, 2019). This introduced women into industrialized processes around the spinning jenny and the spinning mule (New Lanark, 2019). On a side note: a similar explanation can be found in regards to children in carpet production, claiming that small strong hands are best to produce small strong knots (Puetter, 2017) – obviously this technical property does/should not justify use of child labour. In accordance to this logic of innate characteristics, weaving was understood as typically male occupation as the width of the weaving loom and thus the width of the final fabric was subject to the weaver’s (broad or narrow) arm span. While industrial spinning and weaving have widely been replaced by machine operated processes, sewing is still human labour intensive. One may be tempted to transfer the stereotype of nimble fingers with more nuanced sensory to garment manufacturing (see Figure 3).

Figure 3: Representation of typical processes of garment manufacturing show female workers, as found in a standard course book for education in Clothing Technology (Fontaine, 2011:514-519).

This notion of sewing being a woman’s occupation will be linked to historical role allocation as well as the stereotype of women’s affinity for fashion and the resulting specific targeting of this customer group. In her work on ‘Technology, Gender and Fashion’ (2016) Jeanne L. Schroeder challenges this stereotype as a “(…) masculinist approach (…). It is not that the masculine subject is indifferent to fashion. (…) as an empirical matter, men may be more slavish to its dictates than women – for example, a man takes substantial risks if he deviates from the strict sartorial standers of his profession [, e.g. the combo of suit, shirt, tie] (Schroeder, 2016).”

Though limited in frequency, my recollections of men operating sewing machines have never shown any sign of reduced physical ability towards sewing or indicated any other rationale for structural exclusion of males from garment manufacturing. Looking at middle-eastern countries we see historical and contemporary evidence of an active male tailoring community (see figure 4). Textile trade and culture of sumptuous gowns in the Ottoman Empire strengthened the status of tailoring craftsmen and guilds (Yaman, 2012). The garment workforce in contemporary Turkey registered 50.2 percent men (Fair Wear Foundation, 2016:7). A 2014 case study of Istanbul’s tailors contains the following statement: “(…) [When] asked what a typical tailor is like, both women pointed to a man in his late sixties with a mustache and a measuring tape around his neck (Case, 2014).”

Figure 4: Tailors in Istanbul, 2014 (Case, 2014).

Conclusion: Social Construction of Structural Exploitation

In ‘The Social Shaping of Technology’ (1999) MacKenzie and Wajcman refer to a reciprocal relationship between artefacts and social groups. The ‘two-way-street’ entails that social constructions do shape technology but, vice versa, technology does have implications on the social (MacKenzie & Wajcman, 1999:40). Though I would like to welcome this diplomatic and conciliatory standpoint, the technological deterministic interpretation offers too much of an excuse to why the garment manufacturing industry is built on the structural exploitation of women.

“Does [social] constructivism pose a threat to, or provide a potential ally for, the feminist movement? (Grint & Gill, 1995)”

The artefact of “Clothing Technology” was shaped by gender stereotypes and thus stabilized as being female. Having won a rare female space in engineering can be interpreted as success. Seeing the downsides of a female workforce in patriarch societies however, stresses the importance of gaining an equivalent participation in higher institutional levels to manifest feminist decision-making as default. As Wajcman points out: “Engineering culture (…) is archetypically masculine and would have provided an excellent opportunity for an integration of class and gender perspectives on technological change (Wajcman, 1991:48).” Recognizing social constructivism in the industry is the first step towards transforming its power dynamics, increase true gender equality and foremost stop exploitative production systems for trivial mass consumption.

----- Juliet Seger, 2020 -----

RESOURCES

Adidas, 2019. Speed Factory. Available at: https://www.adidas.co.uk/speedfactory, accessed 24/11/2019.

Allen, R.C., 2011. The Spinning Jenny: A Fresh Look. The Journal of Economic History, 71(2), pp.461–464.

BMZ (Bundesministerium für Wirtschaftliche Entwicklung und Zusammenarbeit; German Federal Ministry for Economic Cooperation and Development), 2018. Beitrag der Bundesregierung zur Foerderung von nachhaltigen Textilien (Contribution of the Federal Government to the promotion of sustainable textiles [my translation]). Available at: http://www.bmz.de/de/mediathek/publikationen/reihen/infobroschueren_flyer/infobroschueren/sMaterialie410_roadmap_textilien.pdf, accessed 24/11/2019.

BMZ (Bundesministerium für Wirtschaftliche Entwicklung und Zusammenarbeit; German Federal Ministry for Economic Cooperation and Development), n.d. Bangladesh: Entwicklungspolitische Zahlen und Fakten. Available at: https://www.bmz.de/de/laender_regionen/asien/bangladesch/index.jsp#section-31739573, accessed 21/11/2019.

British Business Bank, 2019a. UK VC & Female Founders Report. Available at: https://www.british-business-bank.co.uk/uk-vc-female-founders-report/, accessed 24/11/2019.

British Business Bank, 2019b. Female start-up founders missing out on billions in funding. Available at: https://www.british-business-bank.co.uk/female-start-up-founders-missing-out-on-billions-in-funding/, accessed 24/11/2019.

Brühl, J., 2013. Faserland (Fibre Country [my translation]), Sueddeutsche Zeitung. Available at: https://www.sueddeutsche.de/wirtschaft/textilindustrie-in-bangladesch-arbeiten-und-sterben-im-faserland-1.1661365, accessed 21/11/2019.

Butkovic, M., 2019. Top 100 Women in Fashion Tech. In: Medium. Available at: https://medium.com/women-of-wearables/top-100-women-in-fashion-tech-388001e40cd8, accessed 24/11/2019.

Case, H., 2014. Istanbul’s Tailors. Available at: https://ecepastandpresent.blogspot.com/2014/02/istanbuls-tailors.html, accessed 25/11/2019.

Degenhardt, J., 2019. Statista Comsumer Market Outlook – Apparel Report 2019. Available at: https://www.statista.com/study/55501/apparel-report/, accessed 24/11/2019.

Destatis (Statistisches Bundesamt), 2019. Studierende an Hochschulen Wintersemester 2018/19. (Students in higher education winter semester 2018/19 [my translation]). Available at: https://www.destatis.de/DE/Themen/Gesellschaft-Umwelt/Bildung-Forschung-Kultur/Hochschulen/Publikationen/Downloads-Hochschulen/studierende-hochschulen-endg-2110410197004.pdf?__blob=publicationFile, accessed 26/11/2019.

Dosi, G., 1982. Technological paradigms and technological trajectories: A suggested interpretation of the determinants and directions of technical change. Research Policy, 11(3), pp.147–162.

Fair Wear Foundation, 2016. Turkey country study 2016. Available at: https://api.fairwear.org/wp-content/uploads/2017/02/CS-Turkey-2016.pdf, accessed 25/11/2019.

Faulkner, W., 2000. Dualisms, Hierarchies and Gender in Engineering. Social Studies of Science, 30(5), pp.759–792.

Fontaine, A., 2019. Technologie fuer Bekleidungsberufe (Technology for vocations in the clothing industry [my translation]), 14th Edition. Cologne: Bildungsverlag Eins.

Friedman, V., 2018. Fashion’s Woman Problem. In: The New York Times. Available at: https://www.nytimes.com/2018/05/20/fashion/glass-runway-no-female-ceos.html, accessed 24/11/2019.

Grint, K. & Gill, R., 1995. The gender-technology relation : contemporary theory and research, London: Taylor & Francis.

Innovation in Textiles, 2017. Automated Sewbot to make 800,000 adidas T-Shirts daily. Available at: https://www.innovationintextiles.com/automated-sewbot-to-make-800000-adidas-tshirts-daily/, accessed 24/11/2019.

MacKenzie, D.A. & Wajcman, J., 1999. The Social shaping of technology Second., Buckingham: Open University Press. Available at: https://eprints.lse.ac.uk/28638/1/Introductory%20essay%20%28LSERO%29.pdf, accessed 30/11/2019.

Mills, M.B., 1999. Thai women in the global labor force: consuming desires, contested selves, New Brunswick, N.J. ; London: Rutgers University Press.

New Lanark, 2019. Visitors walking tour presentation to students of Design For Change MA at The University of Edinburgh, 22/11/2019 [personal communication].

Nike, 2019. Nike Flyprint is the First Performance 3D Printed Textile Upper. Available at: https://news.nike.com/news/nike-flyprint-3d-printed-textile, accessed 24/11/2019.

Pike, H., 2016. Female Fashion Designers Are Still In the Minority. Available at: https://www.businessoffashion.com/community/voices/discussions/how-can-fashion-develop-more-women-leaders/less-female-fashion-designers-more-male-designers, accessed 24/11/2019.

Pinch, T.J. & Bijker, W.E., 1984. The Social Construction of Facts and Artefacts: or How the Sociology of Science and the Sociology of Technology might Benefit Each Other. Social Studies of Science, 14(3), pp.399–441.

Puetter, B., 2017. Kleine Haende, grosser Profit (Small hands, large profits [my translation]. Muenchen: Wilhelm Heyne Verlag.

Schempp, U., 2019. Email from Ulrike Schempp, Professor for Textile Technology at Hamburg University of Applied Sciences to author of essay, 25/11/2019. Available on request.

Schroeder, J.L., 2016. Technology, gender and fashion. Cardozo Arts & Entertainment Law Journal, 34(3), pp.753–806.

Schultze, E., 2014. Exploitation or Emancipation? Women workers in the garment industry. Fashion Revolution. Available at: https://www.fashionrevolution.org/exploitation-or-emancipation-women-workers-in-the-garment-industry/, accessed 21/11/2019.

The Women’s Engineering Society, 2018. Useful Statistics. Available at: https://www.wes.org.uk/content/wesstatistics, accessed 26/11/2019.

Von Wedel-Parlow, F., 2015. Sustainability in Fashion: der Wechsel eines Paradigmas (Sustainability in Fashion: The Change of a Paradigm [my translation]). In: Schulze, S. & Banz, C, 2015. Fast Fashion Magalog. Hamburg: Museum für Kunst und Gewerbe.

Wajcman, J., 1991. Feminism confronts technology, Cambridge: Polity.

Weber-Steinhaus, F., 2019. The rise and rise of Bangladesh – but is life getting any better? The Guardian. Available at: https://www.theguardian.com/global-development/2019/oct/09/bangladesh-women-clothes-garment-workers-rana-plaza, accessed 21/11/2019.

Williams, R., 2019. Robin Williams in course discussion in lecture of course (UT)PGSP11353 in Graduate School of Political Science at The University of Edinburgh, 21/11/2019.

World Atlas, n.d. What Are The Biggest Industries in Bangladesh? Available at: https://www.worldatlas.com/articles/what-are-the-biggest-industries-in-bangladesh.html, accessed 21/11/2019.

Yaman, B., 2012. FIT FOR THE COURT: Ottoman Royal Costumes and Their Tailors, from the Sixteenth to Eighteenth Century. Ars Orientalis, 42, pp.89–101.

---------------

COMING SOON!